The increasing need for pro-active van maintenance

The increasing need for pro-active van maintenance

Published 15/12/25 | Read time 9 min

In January 2025, we published a white paper entitled The 2025 Diesel Van Shortage: How the ZEV Mandate Will Impact Your Fleet. Each month, when the SMMT releases the figures for LCV registrations in the previous month, we see the predictions in that white paper gaining greater relevance.

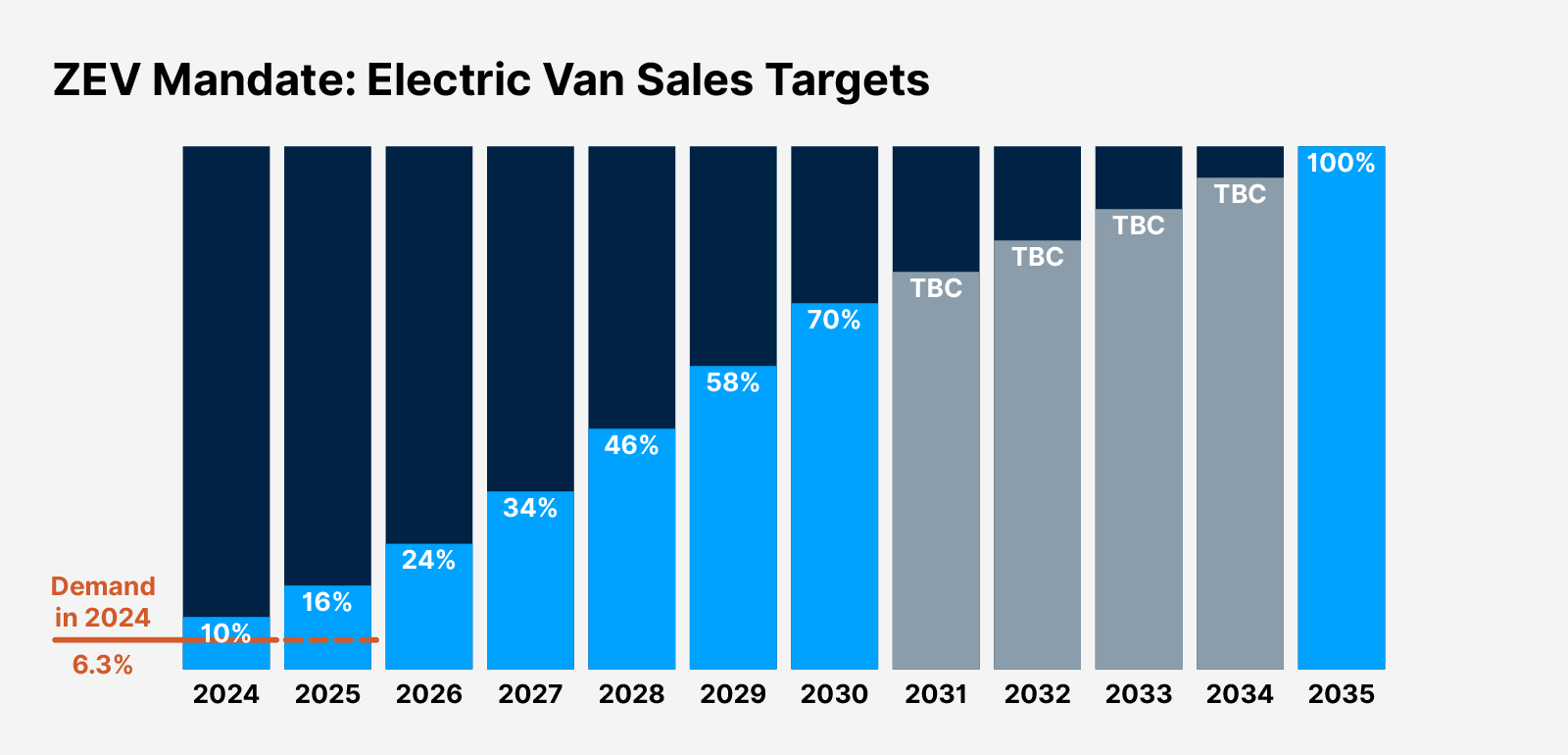

To recap, the Zero Emission Vehicle Mandate came into law at the beginning of 2024 and sets out the minimum proportion of a van manufacturers’ sales that must be electric each year until 2035 when the sales of new petrol and diesel vehicles will be outlawed.

The problem is that many fleets simply aren’t ready to move to electric vans because they don’t meet their needs – that might be down to one or more of a number of reasons, however, the main ones appear to be concerns over range, available charging infrastructure, payload capacity, or acquisition costs and depreciation. Other challenges include inflated running costs if forced to use premium-rate charging.

If manufacturers don’t meet the sales targets then they are supposedly on the hook for massive fines of £18,000 for every non-qualifying ICE (Internal Combustion Engine) vehicle they sell. While the government has introduced some flexibilities to help manufacturers manage the transition, such as borrowing EV credits from future years, these will only store up bigger problems to come if demand doesn’t increase significantly.

Data Source: Society of Motor Manufacturers and Traders

In 2024, fleets bought or leased just over 22,000 new electric vans out of sales totaling 353,000 for the year – a paltry 6.3% against a government mandated target of 10%.

The situation for 2025 was worse than anticipated. While EV sales as a share of total van sales were slightly up at 8.6% for the year, that has to be viewed against a much higher target of 16%. The manufacturers are therefore offering huge incentives to take on electric vans (irrelevant if they aren’t right for your business) and removing discounts from diesel vans, with the result that many fleets are simply sitting on their hands and doing nothing – hence the 15% drop in new diesel van registrations for the first half of 2025.

In order to further encourage demand, the government recently launched a series of initiatives. The reintroduction of grants towards the cost of new BEVs should help, but support will also be needed in the second-hand market if this isn’t to further depress residual values.

The government also introduced a grant scheme where public and private sector organisations can apply for support to install EV charging infrastructure at their depots. While this support is badly needed, it likely won’t have an immediate effect on sales as operators will need to go through a lengthy process of applying for the grant, sourcing a supplier, and commissioning the installation.

All of this reinforces what we at FleetCheck have been saying for over a year now – that fleets are increasingly going to find themselves running older, higher mileage fleets of diesel vans where EVs aren’t suitable and replacement diesels have become too expensive. And this needs major consideration if those fleets are to continue running safe, roadworthy, and efficient vans.

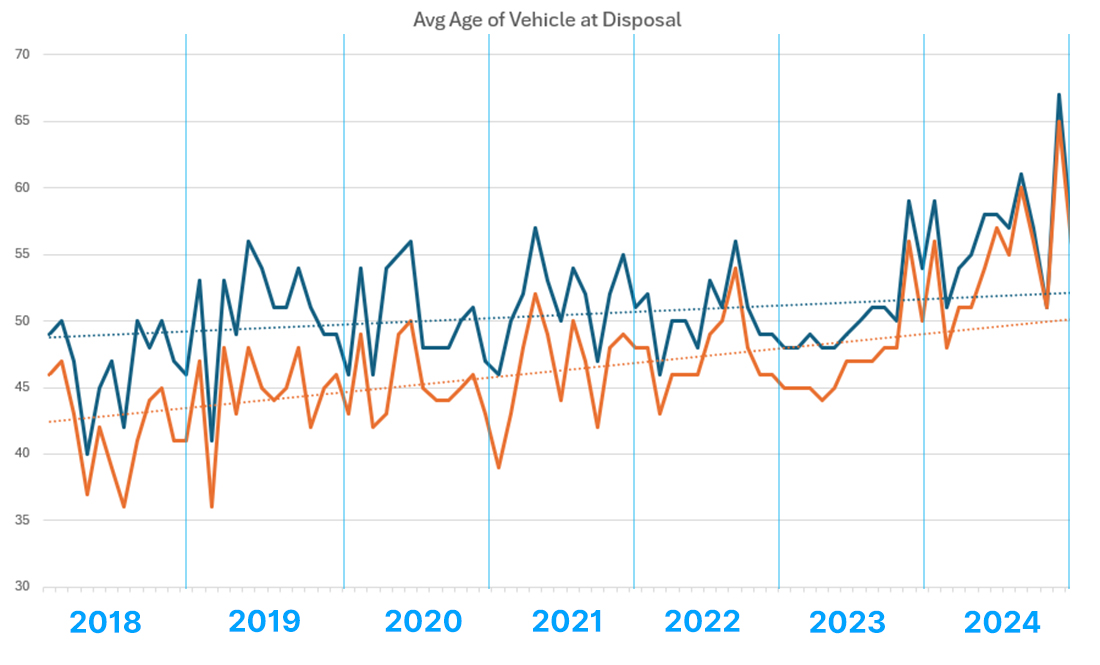

FleetCheck customer data backs this up with 46 months being the average age of vehicles defleeted across the whole of 2018, rising to 68 months for vehicles defleeted throughout 2024.

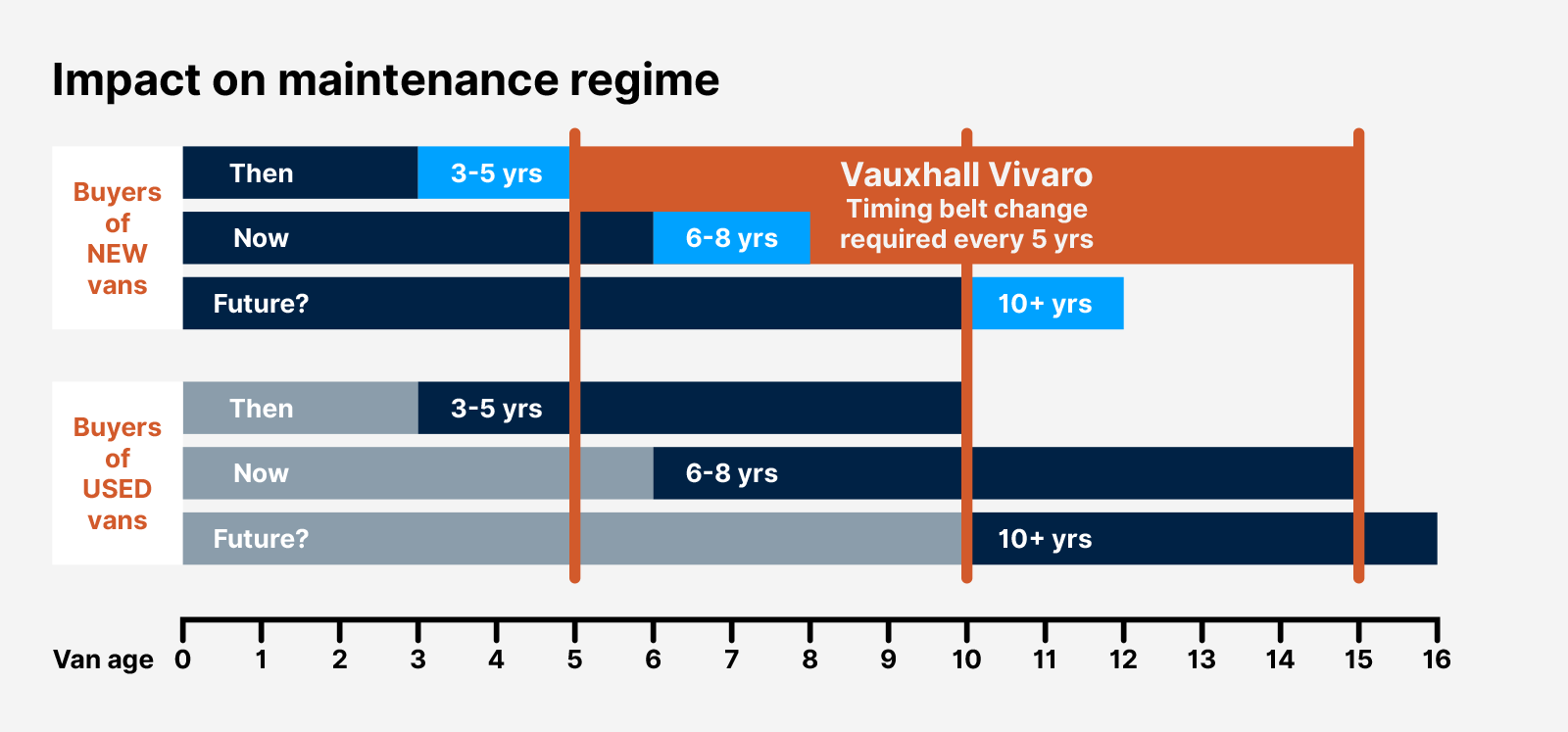

Larger fleet operators used to replace their vans every 3-5 years. Already that’s closer to 6-8 years as many operators look to sweat those assets harder.

Many of the smaller fleets who often bought those used or nearly new vans from the leasing and rental companies or auctions and ran them for 5-10 years, are now having to start their cycles with vans that are already 6-8 years old.

Throughout 2025, we saw fleets that would have bought new vans hold back, because EVs aren’t right for their business. Manufacturers have raised the prices of diesel vans considerably, resulting in a significant drop in new diesel LCV registrations over 2024, and less vans coming into the used van market.

Larger operators are therefore already recognising that they’re going to be keeping their existing vehicles on fleet for much longer and possibly taking used vans out of the second-hand market for expansion, if they can get hold of them.

This means that the supply channels of used vehicles for the smaller fleets are likely to dry up, similar to how they did at the start of Covid with the sudden increase in demand for home delivery.

The result is that, whatever size fleet you run, effective preventive maintenance is going to become vital to guard against unplanned vehicle downtime due to mechanical breakdown and repair, and the drop in service delivery performance that will inevitably follow.

Let’s take a look at some of the new issues operators could face starting with evaluating your maintenance regime.

Maintaining your ageing van fleet: A new era for fleet management

Pro-active fleet management is now more critical than ever. The focus needs to shift from short van replacement cycles to diligent servicing, maintenance, and repair (SMR) regimes to keep these vehicles running safely and cost-effectively for longer.

Fleets must now pay greater attention to routine tasks like timing belt replacements, potentially multiple times during a van’s working life, and address issues of perishable components that perhaps weren’t on your radar before.

If we take timing belts as an example, the belts on a Vauxhall Vivaro need changing every 5 years.

Some operators may have previously defleeted vehicles before a belt change was needed. Now they’ll need to factor that into routine SMR schedules and, in future, they may even need to change the belts twice before defleeting.

Issues with the lifespan of so-called ‘wet’ timing belts on modern vans could also come into play. Issues with longevity have led to Ford recently shortening the belt service interval for some of their diesel vans from 10 years or 150,000 miles down to 6 years or 100,000 miles.

Ignoring manufacturer recalls or MOT advisories on older, high-mileage vehicles will lead to costlier repairs and decreased efficiency, impacting consumables like tires and fuel. Forward planning for SMR is essential due to potential parts availability strains, with some operators even considering retaining older vehicles for spare parts.

Defect management is paramount

Robust pre-use vehicle checks are crucial for identifying minor issues. A strong pre-use checks policy will help ensure that small problems get picked up before they become big problems.

- Underinflated tyres can burn additional fuel and handle dangerously.

- Damaged tyres can become blowouts.

- Oil leaks can become wrecked engines.

- A repairable, chipped windscreen can turn into a full replacement with off-site recalibration required for any ADAS radars and lidars.

Pre-use defect checks are a vital part of your duty of care to both drivers and other road users, but they will also become an essential part of simply keeping older, high-mileage vehicles on the road, so that your business can stay in business.

Effective record-keeping and data collection

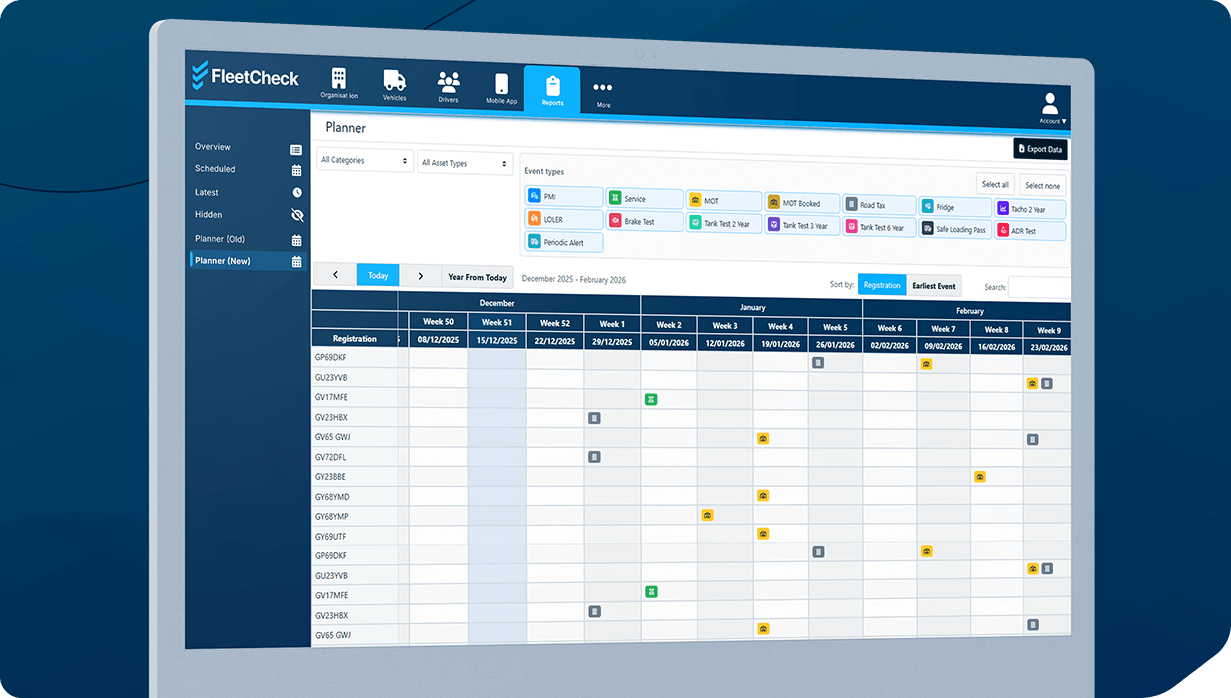

Keeping on top of routine SMR and defect management provides lots of data, identifying wear and tear trends by both vehicles and drivers.

This will help us to track economic viability to prioritise replacement when absolutely necessary, and to keep viable vehicles maintained as a safe and efficient asset.

We therefore need a defect management policy. Ask yourself:

- Do your drivers know what to check and how to report defects?

- Do defects get rectified promptly?

It’s not just about having policies, it’s about following policies - and ensuring these are carried out and recorded properly. Data analysis and reporting will be key to keeping your vans on the road.

Cost-cutting on maintenance is a false economy

Despite budget pressures, preventive maintenance will be the key to ensuring your sales teams, delivery drivers and service engineers stay on the road. Ageing, high mileage vans add an additional safety risk for both your drivers, and other road users, and a financial risk to your business if they aren’t managed correctly. Allowing budget pressures to reduce servicing and maintenance leads to unreliable and potentially unsafe vans that are more likely to break down.

Furthermore, a poorly maintained fleet can jeopardise existing contracts as an increase in unplanned VOR time hits service reliability.

There is a trend currently for clients to demand evidence of good road risk management from their immediate suppliers, as well as evidence that these standards are required further down through the supply chain.

This is already happening in road and rail construction and also some areas of public procurement. With poorly maintained fleets increasingly susceptible to non-delivery of goods and services through breakdown and unplanned maintenance, this is likely to become even more important. No client is going to want a supply chain at the mercy of unreliable vehicles.

In essence, adhering to manufacturer servicing, promptly addressing recalls, implementing rigorous pre-use checks with driver training, and meticulously analysing maintenance data are vital steps to ensure your ageing fleet remains safe, efficient, and compliant.

What to do next

If you’d like to discuss the implications of running a older, higher mileage vehicles as part of your fleet, and how FleetCheck can help ensure your vehicles are as safe and efficient as possible, get in touch.