The changing role of the Transport Manager

A strategic guide to future-proofing your fleet

The Changing Role of the Transport Manager

A Strategic Guide to Future-proofing Your Fleet

The role of the transport manager has fundamentally changed. What once focused primarily on vehicle maintenance and compliance now also demands strategic oversight of complex regulatory frameworks, advanced risk management, and sophisticated data analysis.

Recent high-profile enforcement actions demonstrate the stakes: operators losing licences, directors facing criminal charges, and multi-million-pound fines becoming more common. The margin for error has never been smaller.

This isn't just about minimum compliance standards anymore. Today's transport managers must demonstrate "reasonable and practicable" measures across every aspect of fleet operation while navigating an increasingly complex web of obligations.

The modern transport manager's challenge

Your responsibilities now extend far beyond traditional fleet management and compliance:

- Legal accountability: demonstrating due diligence in all fleet operations

- Risk management: identifying and mitigating operational, legal, and reputational risks

- Data analysis: making informed decisions based on performance metrics and trends

- Technology integration: leveraging systems that support compliance and efficiency

- Stakeholder communication: managing relationships with regulators, drivers, and customers

This whitepaper explores seven critical areas where strategic fleet management can help you meet these evolving demands while maintaining operational excellence.

Are you risk ready and safe?

The real cost of getting it wrong

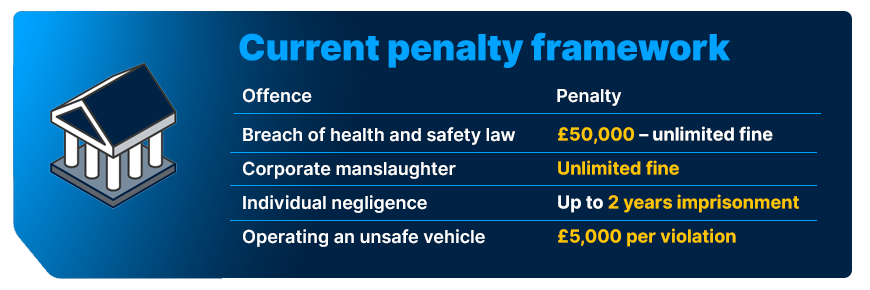

Transport managers today operate under unprecedented scrutiny. The consequences of failure aren't just financial – they're career-ending and potentially criminal.

Consider these recent cases:

Bath tipper tragedy (2015)

Four people died when a tipper truck's brakes failed. The subsequent investigation led to:

- Haulage operator: guilty of negligence

- Mechanic: guilty of negligence

- Both received prison sentences

- The driver was cleared, highlighting how accountability extends beyond the cab

Ward Recycling: £2.15 million fine (2024)

A worker was crushed to death by an onsite vehicle, resulting in one of the largest health and safety fines in the waste sector's history. [i]

K&B Haulage: licence revoked

Stripped of their operator's licence following systematic compliance failures, demonstrating how fleet mismanagement can destroy a business overnight.

Your legal obligations: more than you think

Under the health and safety at work act 1974, transport managers must demonstrate "so far as is reasonably practicable" that they've implemented:

- Safe systems of work for all fleet operations

- Proper maintenance of plant and equipment

- Adequate training, supervision, and instruction

The key phrase is "reasonably practicable." this means you must do everything possible within reason – ignorance, cost concerns, or convenience are not acceptable defences.

The questions that must be able to answer

Can you confidently answer these questions right now:

- Have all your vehicles had a driver pre-use check today?

- Are all your drivers fully qualified and compliant with cpc requirements?

- When did each vehicle last have a roadworthiness inspection?

- Have any drivers failed to disclose recent convictions?

- Which vehicles are showing patterns of defects that could indicate larger problems?

If you hesitated on any of these, you have a risk management problem.

Beyond compliance: building a defence

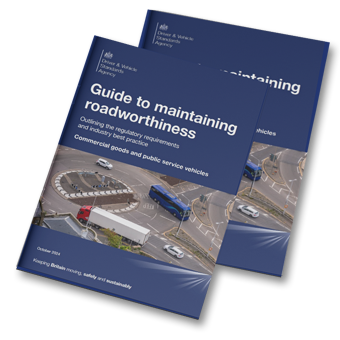

The guide to maintaining roadworthiness (updated regularly by DVSA) emphasises that transport managers must not just follow minimum requirements but demonstrate active oversight and continuous improvement.

This means:

- Daily checks: not just conducted, but recorded, reviewed, and acted upon

- Defect reporting: systems that ensure nothing falls through cracks

- Driver management: ongoing monitoring of qualifications, performance, and compliance

- Documentation: comprehensive records that demonstrate your duty of care

Technology as your safety net

Modern fleet management systems create an audit trail that demonstrates your commitment to safety and compliance. When investigations occur (and they will), having comprehensive digital records can be the difference between a fine and a prison sentence.

The question isn't whether you can afford to implement proper risk management systems. It's whether you can afford not to.

The evolving compliance landscape

Staying ahead of regulatory changes

The regulatory environment continues to evolve rapidly, with new guidance, updated enforcement priorities, and emerging compliance requirements appearing regularly. Transport managers who rely on outdated knowledge or reactive approaches find themselves exposed to significant risk.

Recent updates you need to know

The DVSA regularly update the guide to maintaining roadworthiness, with recent changes focusing on:

- Enhanced requirements for driver competency assessment

- Latest brake testing requirements

- Stricter documentation standards for maintenance records

- Updated guidance on defect categorisation and response times

- New expectations for transport manager oversight and intervention

LCV compliance strategy: the hidden risk

A significant development affecting many transport managers is the DVSA's new enforcement strategy targeting light commercial vehicles (LCVs). Previously, vans and smaller commercial vehicles received less scrutiny than HGVs, but this is changing rapidly.

The new LCV compliance strategy includes:

- Increased roadside enforcement targeting van fleets

- Greater scrutiny of mixed fleet operations

- Enhanced penalties for non-compliance

- Focus on systematic failures rather than isolated incidents

For transport managers overseeing mixed fleets, this represents a fundamental shift in risk profile. Many transport managers find themselves inheriting responsibility for van fleets that were previously managed by other departments or received minimal oversight. While the transport manager may not have formal legal responsibility for these vehicles, the reality is that poor van fleet management can directly impact their HGV operator licence.

Under the DVSA’s enhanced enforcement approach, systematic failures across any part of an operator’s fleet (including LCVs) can trigger investigations that affect the entire operation. Transport commissioners are increasingly taking a holistic view of operator competence, meaning that deficiencies in van fleet management can lead to sanctions against the primary operator licence, even when the transport manager had limited control over these vehicles.

This creates a challenging situation where transport managers must either secure proper oversight of the entire mixed fleet or work with senior management to clearly delineate responsibilities and implement safeguards to protect the operator licence from compliance failures in vehicles outside their direct control.

The traffic commissioner connection

One frequently overlooked requirement is maintaining current contact details with the traffic commissioner's office. Failure to notify changes in circumstances – including contact information, convictions, or operational changes – can result in licence sanctions.

Recent enforcement actions show the traffic commissioner taking an increasingly firm stance on operators who fail to maintain proper communication channels.

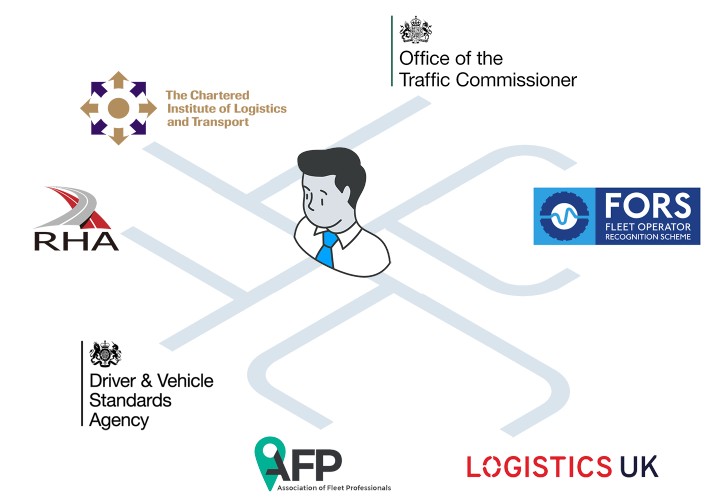

Building your information network.

Successful transport managers establish multiple information sources:

Primary sources:

- Office of the traffic commissioner (OTC) bulletins

- DVSA guidance updates

- Road haulage association (RHA) briefings

- Logistics UK

- Association of fleet professionals (AFP)

- Chartered institute of logistics & transport (CLIT)

- Fleet operator recognition scheme (FORS) updates

Industry intelligence:

- Professional networks and peer groups

- Industry publications and alerts

- Legal updates from transport law specialists

- Technology vendor briefings on regulatory changes

Proactive monitoring

Companies that subscribe to regulatory update services are 40% more likely to avoid non-compliance incidents compared to those relying solely on internal tracking, according to department for transport data.

Consider implementing:

- Automated alerts for regulatory changes

- Regular review cycles for compliance procedures

- Stakeholder briefings on new requirements

- Technology systems that adapt to regulatory updates

Disclaimer and further guidance

This whitepaper provides general guidance based on current understanding of regulatory requirements. For authoritative guidance, always consult:

- The current guide to maintaining roadworthiness (DVSA)

- Your traffic commissioner's office

- Qualified legal professionals specialising in transport law

- Industry bodies such as the RHA, Logistics UK, FORS

- Regulations change frequently, and individual circumstances vary. Professional advice should always be sought for specific situations.

Driver education and accountability

Beyond basic training: strategic driver development

Driver performance directly impacts every aspect of fleet operation – safety, compliance, efficiency, and cost control. Yet many transport managers still treat driver education as a compliance checkbox rather than a strategic tool.

In high-risk sectors like waste management, the consequences of poor driver performance extend far beyond individual incidents. They affect insurance premiums, regulatory standing, customer relationships, and ultimately, your licence to operate.

The modern driver challenge

Today's drivers face increasingly complex demands:

- Navigation of low emission zones with evolving restrictions

- Operation of vehicles with sophisticated safety and monitoring systems

- Compliance with digital tachograph requirements and working time directives

- Customer service expectations in urban environments

- Environmental responsibility and fuel efficiency targets

Data-driven driver management

Successful transport managers use technology to identify patterns and target interventions:

Performance indicators to track:

- Speeding incidents and frequency

- Harsh braking and acceleration events

- Fuel consumption patterns

- Defect reporting quality and timeliness

- Customer feedback and complaints

The question every transport manager should ask:

"Am I acting on this data or just collecting it?"

Many operators generate detailed telematics reports but fail to translate insights into actionable improvements. The data only becomes valuable when it drives targeted coaching, training, or disciplinary action.

Building driver accountability

Effective driver management requires:

- Clear expectations: documented policies covering vehicle checks, defect reporting, driving standards, and customer interaction

- Regular feedback: monthly or quarterly reviews based on objective data, not just subjective observations

- Targeted training: specific interventions based on individual performance patterns, not generic refresher courses

- Consequences: consistent application of disciplinary procedures for non-compliance or poor performance

- Recognition: acknowledgment and reward for drivers who consistently meet or exceed standards

Industry results

Fleets implementing structured driver education programmes report:

- 20% reduction in accident rates

- 15% improvement in fuel economy through eco-driving techniques

- 30% reduction in vehicle defect escalation due to improved daily checking

- Significant improvements in customer satisfaction scores

Beyond compliance: cultural change

The most successful transport managers create a culture where drivers take ownership of vehicle condition, safety performance, and customer service. This doesn't happen through training alone – it requires systems, recognition, and consistent leadership.

Keeping up to date with legislation

The information challenge

Transport managers must stay current with an ever-expanding web of regulations: operator licensing, driver hours, vehicle standards, environmental requirements, and health and safety law. Missing a single update can expose your operation to significant risk.

Essential information sources

Government and regulatory bodies:

- DVSA guidance and updates

- Traffic commissioner circulars and decisions

- HSE guidance for your sector

- Local authority requirements and restrictions

Industry organisations

- Road haulage association (RHA) member briefings

- Fleet operator recognition scheme (FORS) updates

- Professional transport manager networks on LinkedIn

Technology integration

Modern fleet management systems help by:

- Automatically updating statutory deadlines (MOT, CPC renewals, licence checks)

- Generating audit-ready documentation for inspections

- Maintaining current driver qualification databases

Research shows that 42%[i] of fleet managers reported considerably fewer safety incidents since using fleet tracking software to monitor driver behaviour.

Staying connected

Part of this professional engagement involves regularly monitoring your operator compliance risk score (OCRS). The DVSA and traffic commissioners now expect every transport manager to know and understand their score. Being unaware of your OCRS or unable to explain recent changes can significantly undermine your credibility during regulatory interactions.

Your OCRS combines roadside performance with traffic offences to create a risk profile that directly influences enforcement attention. Transport managers who can demonstrate they actively monitor their score and take targeted improvement actions show the kind of proactive management approach that builds confidence with regulators. This data-driven approach to performance management demonstrates the system-based thinking that the traffic commissioners value in professional operators.

Centralise fleet data

From chaos to control

Transport managers dealing with fragmented information systems face unnecessary risk and inefficiency. When driver records exist in one system, defect reports in another, and maintenance schedules in spreadsheets, critical information falls through gaps.

The cost of fragmentation

Disconnected systems create:

- Missed service intervals leading to breakdowns

- Incomplete records during audits

- Delayed identification of performance trends

- Inefficient resource allocation

- Increased compliance risk

The single source of truth

Centralised fleet management transforms operations by providing:

- Real-time visibility: instant access to vehicle status, driver qualifications, and compliance deadlines

- Historical analysis: trend identification for maintenance costs, performance patterns, and replacement planning

- Audit readiness: comprehensive documentation available immediately for any investigation or inspection

- Predictive insights: early warning systems for potential issues before they become problems

Measured results

Organisations implementing unified data platforms report:

- 25% improvement in fleet utilisation

- 60% reduction in audit preparation time

- Significant reduction in compliance violations

- Improved decision-making speed and accuracy

Implementation success factors

- Data quality: ensure accurate, complete information from day one. Your fleet management software provider should be able to support you with this

- User adoption: train staff properly and enforce consistent usage

- Integration: connect all relevant systems and data sources

- Ongoing management: regular review and system optimisation

Simplify workflows with technology

Making technology work for operations

The right technology doesn't just digitise old processes – it makes them more efficient. For transport managers, this means moving from reactive operations to proactive, intelligence-led decision making.

Key integration opportunities

Maintenance data integration

Automated import of service records, warranty information, and defect histories eliminates manual data entry and reduces errors.

Fuel data integration

Fuel consumption monitoring identifies efficiency opportunities and potential misuse.

Tachograph integration

Automated monitoring of driver hours, tachograph calibration dates, and driver card downloads eliminates manual tracking. Key data management for driver card downloads, vehicle unit downloads and 2-year calibration requirements reduce administrative burden through a unified service.

Driver licence checking

Automated checks and re-checks of driving licences and qualification status ensures ongoing compliance.

The pain point solution

Effective fleet management technology addresses specific operational challenges:

- "Which vehicle hasn't been checked today?" – automated daily check monitoring with exception reporting

- "When is the next PMI due?" – predictive scheduling with automatic alerts

- "Are all drivers CPC compliant?" – ongoing qualification tracking with renewal management

- "What's causing high maintenance costs?" – trend analysis and cost benchmarking

Smart scheduling systems can significantly reduce vehicle downtime by aligning PMIs with other upcoming requirements such as MOT renewals, annual tests, or LOLER inspections. Since MOTs can be conducted up to 30 days before expiry without losing time of the certificate, coordinating multiple compliance activities into single workshop visits maximises vehicle availability while ensuring nothing is missed.

Transport managers must move beyond collecting information to analysing and acting on it. This includes:

- PMI data analysis: challenging maintenance providers when inspection findings don't align with usage patterns or previous history

- Performance benchmarking: comparing vehicle and driver performance against fleet averages and industry standards

- Cost trend analysis: identifying vehicles or routes where costs are escalating beyond acceptable levels

- Compliance pattern recognition: spotting systematic issues before they become regulatory problems

When PMIs consistently reveal defects that drivers should have caught, this indicates training gaps that targeted intervention can address.

Technology integrations

FleetCheck provides comprehensive fleet management capabilities and integrates with many specialist solutions, bringing day-to-day fleet management data under one roof. Transport managers should also consider:

- Route optimisation software for improved efficiency

- Advanced telematics for detailed performance monitoring

- Specialised compliance tools for specific regulatory requirements, for example Barbour EHS

- Industry-specific solutions for your operations

The strategic advantage

Technology becomes transformative when it enables better decisions, not just better record keeping. The most successful transport managers use integrated systems to identify opportunities, prevent problems, and demonstrate their commitment to professional operation.

Mixed fleets and LCV compliance

The hidden compliance risk

Many transport managers oversee mixed fleets containing both HGVs and light commercial vehicles (LCVs). Historically, van fleets received less regulatory attention, but this is changing dramatically with the DVSA's enhanced LCV compliance strategy.

New enforcement reality

The DVSA's updated approach to LCV compliance includes:

- Increased roadside enforcement targeting commercial van operations

- Greater scrutiny during facility inspections

- Enhanced penalties for systematic non-compliance

- Focus on transport manager accountability across entire mixed fleets

LCV-specific challenges

Light commercial vehicles present unique management challenges:

- Diverse usage patterns: vans often operate across multiple duty types, from urban delivery to construction site access

- Maintenance scheduling: varied service intervals based on manufacturers recommendation and usage rather than standardised fleet protocols

- Compliance tracking: less standardised reporting requirements but increasing enforcement focus

Transport manager responsibilities

For mixed fleets, transport manager duties extend to:

- Ensuring appropriate licensing for all vehicle categories

- Implementing proportionate maintenance systems for LCVs

- Monitoring driver compliance across different vehicle types

- Maintaining adequate documentation for all fleet elements

- Ensure road worthiness of all vehicles

Strategic implications

Transport managers must recognise that LCV compliance failures can impact overall operator licence standing. The traffic commissioner increasingly views fleet management as a holistic responsibility, not separate HGV and LCV operations.

Best practice recommendations

- Unified management approach

apply consistent standards across all vehicle categories while recognising specific requirements - Technology integration

ensure fleet management systems encompass entire mixed fleet operations - Training and education

develop driver competency programmes appropriate to vehicle type and usage - Documentation standards

maintain equivalent record keeping standards across all fleet elements - Long-term fleet planning

with potential vehicle supply constraints and the ZEV mandate driving extended vehicle lifecycles, develop strategies for maintaining aging fleets effectively

Many operators, particularly local authorities, implement 6-month inspection cycles for low-mileage vehicles that rarely reach manufacturer service intervals. This usage-based approach ensures mechanical integrity regardless of odometer readings and demonstrates proactive risk management to regulators. As the ZEV mandate potentially extends diesel van lifecycles beyond traditional replacement cycles. These proactive maintenance strategies become even more critical for fleet safety and compliance.

Vehicle replacement policies

Strategic asset management

Vehicle replacement has evolved from a reactive process driven by breakdowns to a strategic lever affecting cost control, compliance, and operational performance. With rising disposal costs and tightening emissions standards, replacement timing must be more precise than ever.

Beyond age and mileage

Traditional replacement triggers – fixed age or mileage thresholds – don't reflect actual vehicle condition or cost efficiency in tough operating environments. Smart transport managers use data-driven approaches:

Monthly vehicle profit analysis:

Monthly vehicle profit = revenue - (operating costs + cost of capital)

When profit drops below fleet average, regardless of age or mileage, replacement should be considered.

Leading indicators for replacement:

- Maintenance costs exceeding 8% of revenue for three consecutive months

- Two or more unplanned downtime events per quarter

- Customer complaints linked to specific vehicles

- Repeated failure of the same systems or components

Real-world results FleetCheck analysis of 450+ fleets show operators using data-driven replacement decisions achieve 18-25% better fleet ROI compared to those relying solely on age/mileage thresholds.

A prime example is Adrian White Building Supplies, who discovered through FleetCheck's analysis that maintaining their older vehicles was more profitable than replacement. Despite higher mileage, these vehicles offered superior carrying capacity and had moved past their peak maintenance cost period, delivering better overall value than newer alternatives. This data-driven approach helped Adrian White bBilding[i] Supplies optimise their fleet composition based on actual performance metrics rather than conventional replacement cycles.

Fleet segmentation strategy

Different vehicle types require tailored replacement approaches:

- Urban collection vehicles face different wear patterns than long-haul transport

- Heavy-duty loading operations create distinct maintenance profiles

- Mixed-use vehicles may perform better or worse than specialised equipment

Case study example

One FleetCheck customer traditionally replaced IVECO Dailys at 80,000 miles. Data analysis showed optimal replacement at 95,000-110,000 miles, saving £180,000 annually with no service impact.

Future-proofing considerations

- Emissions compliance: ensure replacement vehicles meet current and anticipated low emission zone requirements

- Technology integration: select vehicles compatible with existing fleet management and telematics systems

- Operational flexibility: consider changing business requirements and customer expectations

- Resale value: factor in market conditions and disposal routes when timing replacements

How to implement this:

- Data collection: comprehensive tracking of costs, performance, and reliability across all vehicles

- Analysis tools: systems capable of calculating true total cost of ownership including opportunity costs

- Decision protocols: clear criteria for replacement decisions based on financial and operational metrics

- Budget planning: replacement schedules aligned with business planning and cash flow management

Conclusion: take control with this 90-day strategy

Transport managers have long understood the operational levers that drive business performance:

- Uptime

- Driver efficiency

- Asset utilisation

- Risk management

- Vehicle health

What has changed is their ability to demonstrate this impact with the comprehensive precision they would like. Where providing value was once challenging, modern systems now provide the evidence base to quantify maintenance strategy outcomes, calculate training roi and measure the tangible value of real-time defect reporting in preventing downtime. Pattern recognition and preventative maintenance capabilities shift the function from cost centre to strategic business partner. One that protects revenue and enables sustainable growth.

Wolseley, one of the uk’s leading merchants in plumbing, heating, cooling and infrastructure, demonstrates this operational evolution in practice. Over three years, their transport operation progressed from reactive compliance management to strategic risk leadership. PMI slippages dropped from 3-4 per month to just 3-4 per year. Tachograph infringement rates fell to 4%. These improvements helped secure a £33 million investment in fleet and transport technology, which generated new revenue streams through third-party contracts and backhauling opportunities.

Perhaps most significantly, when serious incidents occurred, their transport manager Jess Partridge noted: “Five or six years ago, I'd have lost sleep over incidents like that. But now, we’re confident in our systems, we know we’ve done everything right and we're not worried about fallout or negative press.” This confidence, grounded in robust systems and comprehensive audit trails, represents the shift from compliance as a burden to compliance as competitive advantage.

This elevation from compliance oversight to operational leadership requires a structured implementation approach. The following 90-day framework provides a practical starting point for transport managers to establish the systems, processes and evidence base that regulatory bodies expect whilst delivering measurable value to the business.

Immediate actions (today)

Baseline risk assessment

- Download your current OCTS score and identify your worst-performing metrics

- List every system where you currently store fleet data (maintenance records, driver files, compliance documentation) to identify fragmentation

- Review your last three months of daily vehicle check records and identify which vehicles/drivers have gaps

Test yourself: can you answer the critical questions from sub section “building a culture of safety and accountability” right now?

- Which vehicles haven’t had a daily check today?

- Are all your drivers fully qualified and compliant with CPC requirements?

- When did each vehicle last have a road worthiness inspection?

30-day strategic assessment

Risk readiness audit

- Conduct weekly ‘risk readiness audits’ using what you’ve learned from the “are you risk ready and safe” section of this whitepaper

- Map your current information sources against the regulatory monitoring checklist from the “keeping up to date with legislative changes” section.

- Calculate actual replacement costs vs ongoing maintenance costs for your three highest-maintenance vehicles using the monthly vehicle profit formula from the “vehicle replacement policies” section.

- Review your driver performance data using the indicators from the “driver education and accountability” section.

60-90-day implementation

Fleet management system implementation

- Implement the ‘single source of truth' approach. Centralise all fleet data into a unified platform that can automatically track and alert on compliance deadlines.

- Establish automated monitoring systems for licence expirations, training renewal and inspection schedules that eliminate manual tracking errors.

- Create digital evidence trails that demonstrate ‘reasonably practicable’ measures to regulators.

- Begin coordinated scheduling of PMIs with mots and LOLER inspections using integrated systems that optimise workshop visits.

Seven strategic priorities: your action checklist

You have read the strategies. It's time to put them into practice:

1. Risk management

- Set up automated daily check exception reporting with real-time alerts

- Create digital defect escalation procedures with audit trails

- Generate monthly compliance scorecards that track performance trends over time

2. Regulatory compliance

- Configure automated alerts from regulatory updates within your management system

- Schedule quarterly reviews of compliance status with historical trend analysis

- Maintain current regulatory contact details with automatic reminder systems

3. Driver development

- Use integrated data to create targeted coaching programmes

4. Legislative monitoring

- Build automated feeds from the regulatory sources

- Set up intelligent alerts that filter relevant updates to your operation

- Create searchable knowledge bases for regulatory requirements and updates

5. Data integration

- Eliminate the fragmented systems identified in your week 1 audit by moving to unified platforms

- Implement real-time dashboards showing vehicle status, driver qualifications, and compliance deadlines

- Generate automated audit-ready documentation that pulls from all data sources

6. Technology leverage

- Move beyond data collection to automated analysis and exception reporting

- Set up intelligent alerts when PMI findings don't align with historical patterns or usage data

- Use smart scheduling algorithms to coordinate multiple compliance activities and maximise vehicle availability

7. Strategic asset management

- Configure automated monthly profit analysis tracking

- Set up intelligent triggers: for example, maintenance costs exceed 8% of revenue or repeated mechanical failures

The transport manager advantage

Transport managers implementing a strategic approach achieve outcomes that directly protect and enhance their professional standing:

- O licence protection: real-time monitoring and automated compliance tracking help prevent violations before they occur

- Legal defence: comprehensive digital audit trails with timestamped evidence of “reasonably practicable” measures during investigations

- Operational gains: intelligent scheduling systems that coordinate maintenance activities while ensuring nothing is missed

- Professional credibility: data-driven performance dashboards that demonstrate systematic risk management to regulators and senior management

- Career security: automated safeguards that prevent failures, as we saw with examples like ward recycling and k&b haulage

- Strategic value: fleet operations that provide actionable intelligence rather than reactive cost management

The critical decision point

The operator examples we’ve mentioned in this whitepaper did not fail just because they were unsafe. Instead, they struggled because they depended on manual processes and separate systems when strong risk management was needed.

Every day that you operate with spreadsheets and disconnected systems increases your exposure to compliance gaps that can destroy careers and companies. Every manual tracking process reduces your ability to demonstrate the professional competence that traffic commissioners expect.

Modern fleet management platforms facilitate the achievement of strategic priorities by automating complex tracking, analysis, and reporting tasks that manual systems are unable to perform reliably.

The transport managers who will thrive are those ready to adapt, evolve, and lead. The technology exists, and the framework has been proven to change your fleet operations from reactive cost centres to revenue-generating cost centres.

The question isn't whether change is coming. It's whether you'll lead it or be left behind.

About FleetCheck

FleetCheck provides comprehensive fleet management solutions designed to support modern transport managers in meeting their evolving responsibilities. Our integrated platform combines compliance tracking, risk management, and operational efficiency tools to help you demonstrate professional competence and achieve superior results.

For more information about how FleetCheck can support your fleet management objectives contact our team directly.

________________________________________