Reducing VOR Time and Protecting Your Bottom Line

Reducing VOR Time and Protecting Your Bottom Line

Vehicle Off-Road (VOR) - the waste sector’s biggest operational headache, that every transport manager knows intimately.

You understand the cascading impact better than anyone: a tipper or grab lorry unexpectedly coming off the road doesn’t just stop collections but triggers a chain reaction. Productivity halts, standing costs pile up, SLAs are put at risk, and what started as a single breakdown is quickly compounded into an operational crisis.

In an industry where tight schedules and razor-thin margins leave no room for error, vehicle downtime isn’t just an inconvenience – it’s a profit killer. As the old trucking adage goes, “if the wheels aren’t turning, you’re not earning.”

Yet, despite this universal understanding, VOR can continually challenge the most experienced of operations. The question isn’t whether you know you have a VOR problem – it's whether you have the most appropriate tools and frameworks to tackle the structural challenges that make it so persistent.

Why Measuring VOR Remains Your Foundation

You can’t manage what you don’t measure. Too often, downtime reporting is fragmented across spreadsheets, incomplete workshop records, or memory. This makes identifying patterns, justifying investment, and holding suppliers accountable nearly impossible.

The cost impact is immediate and substantial with unplanned vehicle downtime can cost businesses between £3,000 and £4,000 per day, with an average of three VOR days per year not unusual. These costs can come from:

- Standing costs of idle vehicles

- Lost revenue from missed collections

- Vehicle Recovery

- Additional rental or replacement vehicles

- Transferring tools and equipment

- Workshop overtime or third-party repair costs

Tracking and benchmarking these figures should be standard operating procedure – not just for cost control, but to identify inefficiencies, and help underpin investment decisions.

Unplanned downtime can erode client trust, damage valuable partnerships, and create knock-on effects across your entire supply chain.

To optimise operations, maintain compliance, and safeguard your bottom line, you must monitor VOR-related expenses closely and benchmark them against industry standards.

Common Causes of Fleet Downtime

Driver Behaviour

Aggressive driving – such as harsh braking or speeding – not only increases accident risk but also contributes to the premature wear and tear on vehicle parts, ultimately compromising overall fleet safety.

Older, Higher Mileage Vehicles

While 45% of fleet vehicles are less than 4 years old, waste management vehicles often need to operate well beyond this life-cycle, all while enduring intensive daily use and harsh working conditions. Older vehicles are more difficult to keep roadworthy and therefore more prone to breakdowns.

Poor Maintenance

Maintenance is a critical part of overseeing a waste management fleet, and how you handle it can have a huge impact on your costs and uptime. Many breakdowns often result from damaged or faulty equipment which could have easily been detected during routine inspections.

For operators pursuing accreditations such as DVSA Earned Recognition, this level of insight isn’t optional. VOR tracking and maintenance performance data are key indicators of safety and reliability standards, and they need to be auditable, not anecdotal.

Proactive Strategies to Reduce Downtime

and Keep Fleets Moving

Act on Your Telematics Data

Driver behaviour directly impacts component lifespan and vehicle reliability. But the key isn’t just collecting telematics data – it’s acting on the data with targeted interventions. The most effective operators:

- Monitor driver scorecards and telematics data to flag high-risk drivers early

- Conduct targeted training based on real data and driving patterns

- Implement a robust driver induction programme, including driver assessments, to ensure drivers are fully aware of their responsibilities

- Regularly review and reinforce a clear Driving for Work policy

Tighten Your PMI Schedules

Meeting the legal minimum isn’t the same as best practice. Most waste fleets operate in harsh working conditions: stop-start driving, heavy payloads, short trips, and constant hydraulic use. This makes PMI strategy critical. Take Wolseley, a long-term FleetCheck client. They moved from an 8-week PMI cycle to 7, which:

- Reduced PMI slippages tenfold

- Significantly cut defect rates

- Improved repair forecasting and parts ordering

Fleets that treat PMIs, not just as compliance, but as an opportunity to optimise performance, will ultimately see the biggest gains in uptime and long-term vehicle health.

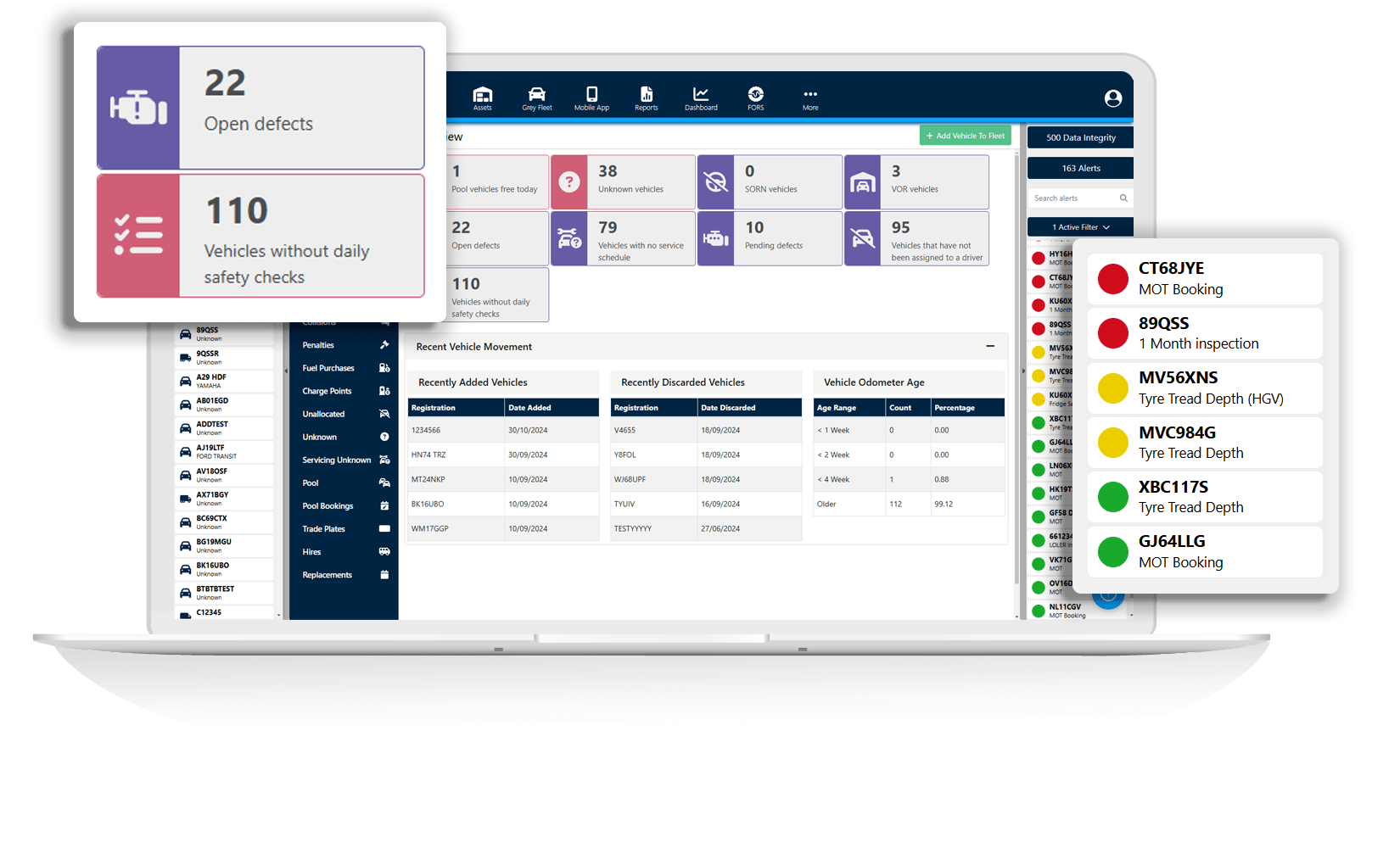

Use Digital Fleet Oversight

Digitalised systems bring consistency, visibility, and accountability to your maintenance and compliance efforts. With a fleet management system, operators gain:

- Real-time tracking of inspections, defects, and service events

- Integrated alerts to avoid missed deadlines

- Centralised visibility across all assets and locations

Aligning PMIs, MOTs, defect rectifications, and service events in one digital workflow means you can save time, stay compliant, and stay ahead of problems before they result in costly vehicle downtime.

How FleetCheck Can Help

VOR isn’t just a maintenance issue – it’s about forecasting. FleetCheck provides full visibility over fleet operations, giving you the tools to pre-empt issues before they materialise, offering actionable insights that go beyond compliance and help you reduce VOR.

FleetCheck delivers:

- Full visibility over maintenance events and defects

- Proactive maintenance scheduling

- Rapid defect resolution

- Accountability across workshops, drivers, and managers

- Smart prohibition risk mitigation through early warning indicators

- Integration with existing systems and supplier networks

6 in 10 FleetCheck customers report that our system has reduced unplanned vehicle downtime, with London Borough of Tower Hamlets achieving an 100% reduction in unexpected downtime.

FleetCheck manages all our MOTs, PMIs, and road taxes, flagging important events with an exclamation mark to alert us, it’s really good. Plus, I can input mileage data to track vehicles with excess mileage, and we can generate a wide range of reports.

Paolo Necchi | Assistant Fleet Manager